Pacific Plug & Liner Invests in New Planting Line Technology

Growers are automating to reduce labor, improve efficiencies, and boost crop quality and uniformity. These points are especially important for young plant growers, who are supplying plugs and liners to growers of all sizes around the nation. As such, Pacific Plug & Liner (PP&L) in Watsonville, CA, which specializes in producing perennial young plants, showcased its recent investments at the 2018 California Spring Trials, providing visitors with a look behind the scenes to see improvements on the operation’s planting lines.

Front of the Line Innovation

First off, PP&L has recently adopted the Growcoon propagation system to amp up the vitality of its young plants. A biodegradable tissue with an elastic yet open structure, the Growcoon holds growing substrate together in propagation systems without compaction, to support faster root development and formation of a stable root ball, to offer optimal growth conditions for young plants.

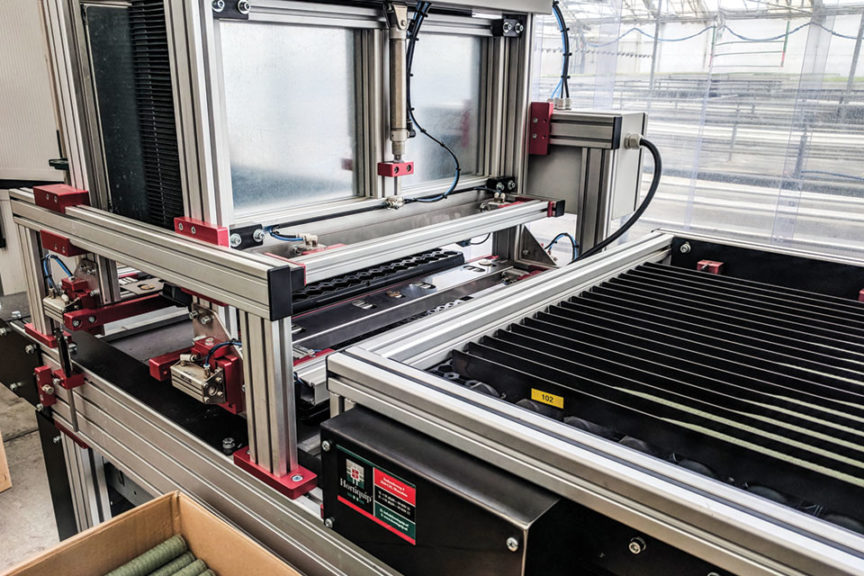

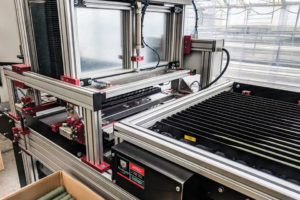

Developed by Maan Biobased Products and distributed by the Klasmann-Deilmann group, the Growcoon can be used in all common propagation systems and trays, and can be placed in trays manually or with an automatic dispenser, developed by Flier Systems. At PP&L, this dispenser fits in well at the front of the line to reduce labor and increase efficiency.

Without disruption, it adds another machine to the line, further mechanizing the planting process and saving on expensive labor. A standard dispenser, fitted with a tray-unstacking unit and conveyor belt, costs the approximately $30,000 to $35,000.

Stacks of Growcoons in the dispenser are automatically unstacked and placed in trays for filling further down the line. In each cycle, the dispenser places a full row of Growcoons across the width of the tray. The number of holes per row determines the speed of the dispenser, which fills a row every 1.4 seconds and can place up to 50,000 Growcoons per hour. Divider racks allow PP&L to change the Growcoon size needed for different trays. So far, the young plant grower is using Growcoons for four different tray sizes: 72, 102, 128, and 162 cells.

Cutting Planter Robot Offers Long-Term Savings

Once trays have Growcoons and are filled with quality substrate, they move down the line to the ISO 2500 Cutting Planter from ISO Group. PP&L General Manager Marlon Carrera says the company has ordered two more of the machines due to the clear benefits and long-term savings it offers. The new machines should arrive by October, he says, and will include the new option for including dip hormone as part of the software functionality, without any additional hardware.

The ISO Cutting Planter requires only one operator, and can stick up to 2,500 cuttings per hour, though PP&L has realized efficiencies of up to 2,700 per hour. The machine automates the heavy, monotonous manual work of planting cuttings, and allows PP&L to move labor to higher-value areas.

More Automation on the Way

Carrera says PP&L is investing in additional technology to further streamline production. In July, PP&L will replace 22 irrigation booms with the help of Cherry Creek Systems. At least two of these will be enabled with technology to operate from smart phones. Once growers test this technology, it may be added to the other 20 booms, Carrera says. PP&L also plans to upgrade all of its shade curtains, and has extensively improved its propagation area with new sidewalls and a fog system operated by Argus sensors, allowing the operation to keep adequate humidity for success in that part of the growing process.