Talking Shop: Metrolina’s Quest For Clean Water

Talking with the rest of my peers in the industry, it has become evident that growers’ most common hopes and dreams have to do with better water to start with, and water treatments that will give crops a better chance to succeed.

Talking with the rest of my peers in the industry, it has become evident that growers’ most common hopes and dreams have to do with better water to start with, and water treatments that will give crops a better chance to succeed.

I remember talking to the VanWingerdens years ago, when they asked me, “If there was one thing you would like us to give you, or improve on, what would that be?”

It took me two seconds to reply, “Clean, very clean water.”

[blackoutgallery id=”64381″]

Since then, the company and its ownership has made numerous decisions and tested virtually everything on the market — charcoal filters, sand filters, glass filters, ultraviolet light, distilled water, chlorine — you name it we have tried it. Then came the evolution of ozone.

How We Got Started

The operation’s first water source was the wells that were able to supply enough water for about four to 10 acres in the early 1970s, when Tom VanWingerden started the company. Then the first pond was build on a half acre to supply and add to the wells. Years of rapid expansions followed. Metrolina grew from 20 to 40 acres, then to 100 acres in the early 2000s. The second pond was built in 1984 and the first sand filters were added to take off the larger particles.

During all those years, great plant quality, marketing and a rapid market expansion — and therefore a need for a better and healthier product for the consumer — has driven us to continue testing, evaluating and implementing everything new that comes on the market. We want to give the homeowner a better start with the plants they are taking home, to showcase their effort and creativity.

This all stemmed from one idea — send the best plants there can be, and grow them to last

Metrolina Has A Lot Of Water To Treat

Metrolina Greenhouses sources nearly 100 percent of its water from rain and irrigation runoff. For every inch of rain that falls on the greenhouse, our roof and pond system allow us to collect and store 3 million gallons of water in 25 acres of retention ponds, which is then treated, stored in tanks and delivered to the greenhouses to water plants.

In volume, Metrolina used 125 million gallons of treated water last year, for an average of 340,000 gallons per day.

A second pond and a well serve as a backup for rainwater. With the huge amount of material we are growing to a higher standard, you can imagine how important getting a good start is.

We had a feeling water could be affecting all stages of production, from 300 million seeds and 80 million cuttings to 380 million plugs and liners and $150 million worth of finished plants.

We worried that our water was not as good as it could be and that it was holding back growth. This is how we started talking with the Dramm folks and Advanced Treatment Technologies’ Charlie Hayes about ozone treatments and the benefits of integrating such a system.

It was a slow start — something very unusual for us — that began with visiting other growers, including Fisher Farms in 2009 and Lucas Greenhouses in 2010.

Testing And Comparing Ozonated Water With Well And Pond Water

Setting up, meeting and testing protocols took a little bit of time, but at the end of 2012, we were ready. Dramm brought us a portable system that could be hooked to multiple booms, and the testing began:

We placed three different treatments side by side:

• Well water

• Pond water

• Ozonated pond water

Fourteen crops were sown from the same seed lots on the same day and with the same fertilization schedules and growing techniques.

The data was recorded as follows:

• Daily DO ( dissolved oxygen readings and comparisons)

• Daily ORP readings (Oxidation Reduction Potential)

• Weekly soil and tissue samples were sent to the labs

• Weekly photos were taken and side-by-side comparisons made

• At the transplant stage, dry mass measurements and comparison

• Timing between the three treatments

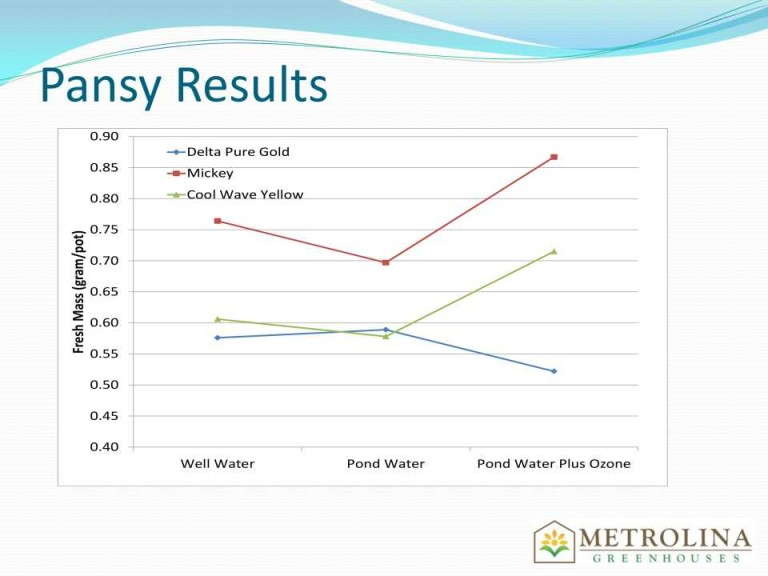

What we found encouraging was that most of the seedlings that were sown and treated with ozonated pond water showed similar, and in some cases better results, in comparison to even well water.

For example, pansies have show greater dry mass improvement in 75 percent of cases, compared to the regular pond water.

Root development also was very satisfactory. The roots or root hair was greatly improved when ozonated pond water was used to irrigate those seedlings. Germination rates have increased, as well.

In the next case study, we took the same lots and four colors of the Hurrah petunias sown side by side, but a week apart. The ones that were sown one week later, but treated with ozonated pond water, made up the time. In the end, they were at the same growing start or better, with a better germination rate, compared to the plants that were sown one week earlier.

Metrolina’s Complete Water System Has Provided Many Benefits

Throughout the process, the ownership was 100 percent involved and participating in negotiations, as well as engineering and installing the systems.

With full implementation of the current water system, this is what Metrolina has today:

• Pond Aeration system

• 2 submersible pumps mounted on floating decks each pump 1,000 gallons per minute

• Sand filters w/glass media

• 5-micron pre-filter

• Ozone generator

• Ozone mixing tank

• 5-micron post-filter

• Copper ionization

• 500,000-gallon storage tank

Today, Metrolina’s water system includes a 100 percent operational pond, with aeration and ozone treatments for all the water that enters the greenhouse.

The system has aided in:

• Reducing timing and adjusting schedules for most of our plants

• Delivering healthier and happier plants to the stores

• Reducing dump rates to a minimum, in comparison to the past

In the end, delivering a proper level of dissolved oxygen to plants has provided many benefits:

• Increased nutrient uptake and conversion efficiency

• Increased beneficial bacteria population, while excluding harmful bacteria population

• Reduced plant stress, improving immune system response, and therefore its resistance to disease

It is a well-known fact that a plant’s roots require dissolved oxygen. A healthy plant is an efficient plant.

For our company, this has been a very positive move forward, and we are happy with the new addition to our water treatment arsenal.