A Fun and Useful Way to Maximize Manual Transplanting

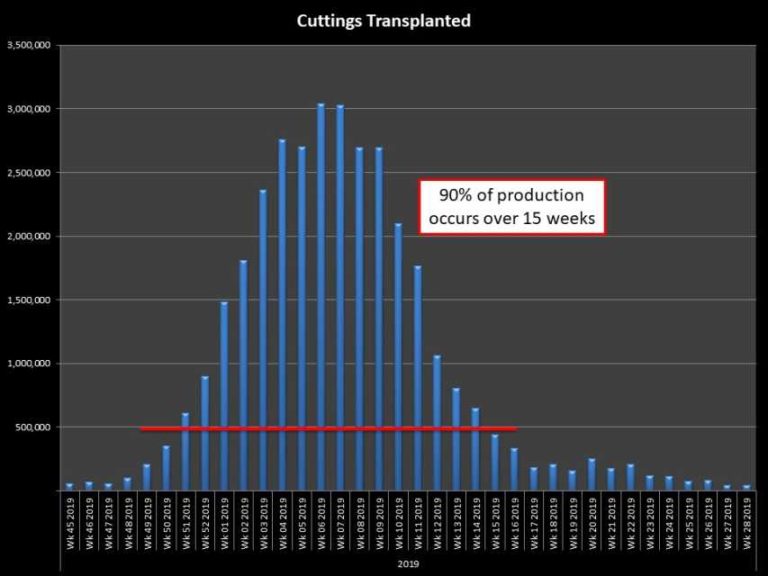

Transplanting of cuttings is one of the most labor-intensive and highly seasonal activities for young plant operations. Each winter, businesses have to rapidly hire and train staff to meet the peak demand.

Automated transplanting is being adopted by some large and innovative young plant growers and can increase labor efficiency. The first steps toward automation, however, is to maximize productivity of your manual process with a modern, clean, and efficient manual transplant line, to quantify the cost of manual work and evaluate return on investment of new equipment. The diversity of genetics and tray sizes common in most greenhouses means that manual sticking of cuttings remains an essential activity, even in largely automated operations.

Over the past four years, we have conducted research at the University of Florida (UF) on manual and automated transplanting of cuttings as part of the Floriculture Research Alliance program. We have been impressed by both the excellent supervisors and team leaders who train and motivate their staff, and the hard-working and diverse stickers in our industry who undertake repetitive tasks for long hours on the transplant line.

To help motivate transplanting crews, recognize excellence, and provide a fun pre-season tune-up, in winter 2019-2020, we ran a pilot training activity called “Stick Olympics” with several growers in Florida, Michigan, New Hampshire, New Jersey, and North Carolina. This article describes our approach to Stick Olympics, along with other tips on how to train a diverse seasonal staff. This exercise was pre-COVID-19, so please adapt your training in a socially distanced, safe way.

Our Stick Olympics Approach

- To provide reproducible results between operations and avoid disease issues, my UF students “harvested” two-node plastic cuttings from boxwood garlands purchased online.

- These “cuttings” were organized into sets of 105 cuttings in zip-lock bags that were sent to several young plant operations.

- The competition emphasized speed, with a race to stick a full tray of cuttings. Transplanters followed close to their standard local procedures (working at transplant stations, gloves and/or hand sanitation, and with local tray sizes). At the start of each round, cuttings were in the closed plastic bag. Hands in the air indicated the tray was completed.

- However, quality is also important. Before starting, we discussed quality aspects such as cutting orientation (not upside-down), no missed cells, cutting placement in the center of cells, cutting depth and its effect on rooting, and the importance of transplanting to the success of the business. This discussion also established the rules for a valid transplanted tray during the exercise.

- Feedback was also provided on technique between rounds, and staff were encouraged to make some noise. Rockwell Farms won the competition for the loudest group!

- Time was recorded on smartphones with multiple timekeepers, with preliminary knock-out rounds leading to five to five finalists.

- Individualized certificates from the University of Florida Institute of Food and Agricultural Sciences Extension were provided to all finalists, along with prizes for winners and lunch sponsorship from the Blackmore Co. in an award ceremony.

What We Learned

- The biggest concern for managers and myself during the Stick Olympics was that the exercise needed to be fun and positive, rather than overly competitive and divisive. This was helped by providing a sponsored lunch for all, having human resource staff on hand to ensure fairness, and encouraging enthusiastic support from management and staff from other parts of each greenhouse. Adding in a loud “stick off” round where managers transplanted cuttings allowed staff to turn the tables, laugh, and provide advice to their supervisors .

- Not all the fastest transplanters had the same technique. Some key elements depend on the individual in terms of rapid hand speed and dexterity. One grower, Pleasant View Gardens, uses a Purdue Pegboard Test to help screen new staff for dexterity.

- Other aspects can be trained: Minimize the distance for total hand movement from the pile of cuttings to the cell where the cutting is transplanted. Have both hands work together either by using one hand to orient and deliver the cutting to the sticking hand, or transplant using both hands. Work across or down the tray to ensure all cells are filled without misses.

- At one grower location, staff reduced sticking time from 160 seconds to 124 seconds from the first to final round, as transplant technique was discussed and honed (and as staff became used to the plastic cuttings and were less nervous). That improvement in speed is the equivalent to seven more trays transplanted per hour.

- The fastest transplanter (Martin Flores at Pleasant View Gardens) stuck a tray of 72 cuttings in 64 seconds. That is equivalent to more than 1 cutting per second or 4,050 cuttings per hour. At all locations, the fastest stickers were able to transplant the equivalent of more than 2,500 cuttings per hour.

- It is not possible to keep that speed up for an eight-hour shift, but our previous studies at 14 large greenhouses found an average of 900 cuttings per hour, with the most efficient operation transplanting 1,360 cuttings per hour during the peak week, and the most efficient worker reportedly at 2,000 cuttings per hour.

- Managers were sometimes surprised that employees who were rather slow in their day-to-day work could really turn it up in competition. In follow up discussions with managers, topics included developing standards for a baseline number of cuttings transplanted per worker per hour, having clear productivity goals, and providing incentives for exceeding standard productivity either by the individual or team.

The Benefits of Training

Most growers train by job shadowing (putting new staff next to experienced workers), and it is worth spending the time to observe and discuss the how and why of transplanting. We have developed training videos to help on-board new transplanting staff who may have no background in horticulture. These training videos are available in English and Spanish at BackPocketGrower.org under “Training” and “Cutting Propagation”. It might seem simple to stick cuttings, but there are actually many training elements.

- Explain why a team member should care and how their job is important: Transplanting is a link in a connected production chain. Help stickers appreciate the downstream impact of their activities on their co-workers out in the greenhouse and in shipping, and the success of the overall business. Show staff the greenhouse area, the final rooted product at the end of the growing cycle, and a brief overview of the business. Some motivated staff will seek future roles elsewhere in the operation.

- Parts of the plant (including the base, nodes, and leaves, and the top and bottom, which are not always obvious with stem cuttings)

- The effect of planting depth on rooting and the importance of centering the cutting in the tray

- Physical damage, pest or disease issues to check for, how cuttings can be damaged during handling, and the cost if damaged or off-sized cuttings are planted that need to be graded later

- The dollar value of each cutting

- Specific requirements for different species

- Techniques for single, double, and triple-sticking of cuttings into a single cell

- The need to keep the cutting hydrated

- What to do at the start and end of breaks, for example, partially transplanted trays

- Personal hygiene, smoking, and their effect on health of co-workers and plants

- Safety and ergonomics

- Sanitation of the work area, and final cleanup of the work area and end-of-day activities.

Most operations we visited had benefited from a lean flow consultant to review aspects tracking each tray with the employee name, recording individual and/or team goals and performance on visual scoreboards, and minimizing wasted movement such as each grower having to stand up and get their own fresh cuttings and materials.

Although some growers use progressive sticking (two to three employees collaboratively filling partial trays), other growers are very productive with one tray per staff member. At Spring Meadow Nursery, we had teams of three doing progressive sticking for Stick Olympics — it was chaotic, but worked out!

We hope this article provides ideas to help increase productivity of your manual transplanting, and ways to recognize and motivate your seasonal staff. The greatest resource in any business is our people, and diversity is a strength.

We thank the hard-working folk at D.S. Cole Growers, Kube Pak Corp., Lucas Greenhouses, Pleasant View Gardens, Rockwell Farms, Speedling, Spring Meadow Nursery, and Walters Gardens who participated in Stick Olympics. It is an honor to work with these leading growers and their staff. Thanks to the generous sponsorship of Blackmore Co. and other partners in the Floriculture Research Alliance, and to our UF students for “harvesting” thousands of plastic cuttings.