Breaking Down Wood Substrates for Container-Grown Plants

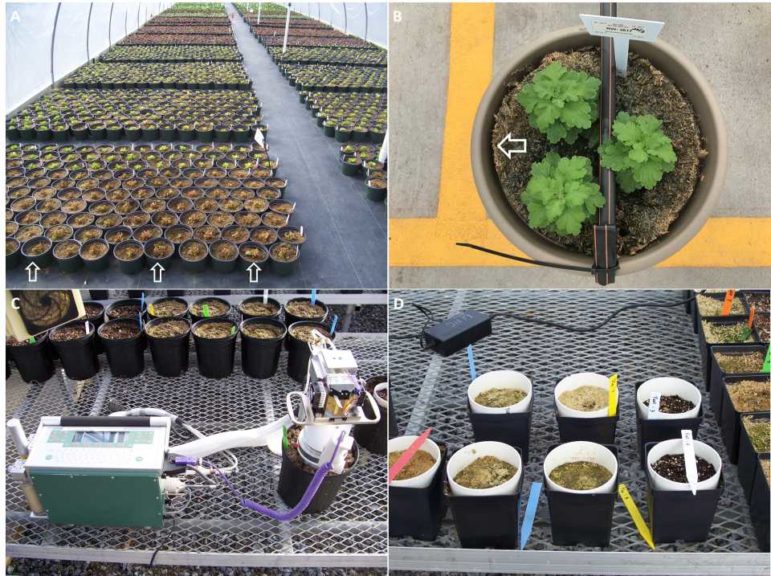

For container-grown plants, the stability of the physical properties of soilless substrates is of primary concern because changes in these properties may negatively affect production management strategies and plant growth. The change in the physical nature of a substrate could be due to one or more factors, including segregation of substrate particles resulting in settling, shrinkage due to drying, microbial decomposition of organic matter, and/or physical breakage of particles (Photo slideshow: Figure 1A-1B). It is important to note that substrate shrinkage away from the sides of containers or slumpage (volume loss) in containers may be a result of improper pot filling, inadequate moisture content at the time of potting, or the nesting/settling of the substrate components into one another after irrigation.

If substrates are subject to rapid microbial decomposition, the microbial population could compete with the plants in the container for available nutrients (e.g., nitrogen and sulfur). The rapid utilization of oxygen by the microbes (plus the reduced pore space and gas exchange properties of the degraded substrate) could create anaerobic conditions, especially after irrigation and in the lower portion of containers. This first article will focus on the causes of substrate degradation and some research results on the stability of some wood materials. The second article in this series will provide specific data on the stability of several commercial wood substrate products/mixes and long-term stability in containers.

Decomposition 101

Bacteria and fungi are the principal agents of decomposition within a substrate (or soil) and are collectively known as decomposers. Every naturally occurring organic compound can (and will) be decomposed, either by single micro-organisms or by different species working in combination and/or at different times. Fungi (white and brown-rot as examples) are usually the initial decomposers seen on organic material, as they often attack the cellulous of wood first (Photo slideshow: Figure 2).

Microbial decay can occur in wood chips during storage if not dried, as well as during cultivation when mixed into a substrate and provided with water and nutrients. Microbial populations in a container during plant production can also vary in size due to substrate pH, available nitrogen, temperature within the container, and level of salts (EC) of the substrate. One of the primary methods of measuring microbial populations as a means of assessing substrate decomposition rates and potential is by measuring the CO2 emitted from the substrate (Photo slideshow: Figure 1C-1D). As microbes degrade carbon materials, they consume oxygen and release CO2, which can be captured and measured.

Factors That Impact Decomposition Rates

Chemical factors influencing decomposition rates (stability) include the percent cellulose of the organic matter, which plays a major role in decay rate and microbial nutrient immobilization since it breaks down rapidly. Lignin is another important constituent of wood and is more resistant to microbial decay than cellulose. The percent of cellulose and lignin in wood is dependent on tree species as well as whether the tree is softwood (pine) or hardwood.

Another important consideration relative to wood substrate materials is whether the wood products contain the bark from trees or not. Bark can have wide-ranging variations in cellulose composition with hardwoods having higher percentages (~40%) compared to softwoods (~5%). The last major chemical factor affecting wood decomposition is the presence of polyphenols and other wood metabolites that can be resistant to microbial attack.

Physical factors affecting decomposition rates include the particle size of the organic materials. The smaller the particle size, the greater the surface area, which gives more surface access for microbial attack. Some substrate materials, including wood, can also have internal spaces and surfaces that, if colonized by microbes, can increase decomposition rates. Reports in the literature also suggest that the ease of wetting of organic particles can also influence microbial decay. Research suggests that in some situations, the water-insoluble resins found in the wood of pine species, the wax on peat fibers, and the suberin found in some softwood barks can prevent or minimize surface wetting, thereby limiting microbial growth.

Hardwood Versus Softwood

Research trials since 2005 have evaluated many aspects of wood decomposition and its simultaneous effect on nutrient availability, air-water relations of the root zone (substrate), and overall plant growth and performance. The data from these trials has supported what other scientists have previously reported about the decomposition rate of wood materials, with the difference being the more recent research efforts focused on wood stability/decay in containers during plant production.

One of the most seen results is that wood materials from softwood, primarily pine species, degrade less rapidly than hardwood species. In fact, even when plants were grown in 100% wood substrates, the color of the pine wood rarely ever changed over the course of 12 to 14 weeks during plant production (Photo slideshow: Figure 3A-B), unlike hardwood species such as maple, ash, sweetgum, poplar, and sycamore (Photo slideshow: Figure 3C-D).

To date, hundreds of annual and perennial species have been grown in numerous different wood products, at varying percentages, and in various indoor and outdoor grower facilities across the U.S. with similar reports of stability and minimal wood color change. Have there been reports (communications) of wood substrates degrading, changing colors, robing nitrogen, and negatively affecting plants? The answer is yes. However, most of these incidents have been identified as issues relating to wood greenness (fresh), use of sawdust materials, hardwood species, etc.

What About Nutrient Immobilization?

Other research trials aimed at observing and quantifying decomposition rates and nutrient immobilization in wood substrates (hammer-milled products) have included greenhouse evaluations of wood materials produced from different tree species, particle sizes, and blending ratios with peat. Evidence of the color retention of processed pine wood compared to sycamore (hardwood species) can be seen in Photo slideshow: Figure 4. In this trial, containers filled with wood substrates had varying amounts of nitrogen added to them. They were irrigated weekly and monitored over 14 weeks. Over that time, degradation of the hardwood species tested was evident, unlike pine. These trials helped confirm what growers and researchers were seeing in production trials and helped provide some confidence that if pine wood was manufactured correctly, it would remain stable and of natural color over the course of even longer-term greenhouse crops.

Decomposition Over Time

Other stability trials were conducted on processed pine wood in outdoor conditions to observe decomposition rates and overall changes of wood over time. In this trial, piles (8 cubic yards each) of processed, unamended (no lime or nutrients added) loblolly pine tree substrate were placed outdoors, covered with a screen to prevent debris contamination, and exposed to the elements for one year (Photo slideshow: Figure 5A). After a year, the piles were sampled (outside and middle) and analyzed for changes in physical and chemical properties (Photo slideshow: Figure 5B). At that time, fresh pine tree substrate was made using the same processing parameters as before and compared to the one-year-old stored material (Photo slideshow: Figure 5C).

Results from this trial indicated that the particle size of the stored wood substrate was within 4% of the fresh material, and the color had not changed. For comparison, a batch of the same substrate produced and stored outdoors for one-year was potted in 3-gallon nursery containers, amended with lime and controlled-release fertilizer, and placed under outdoor irrigation on a nursery pad for the same one-year time frame. Under those conditions, the substrate did change color (to dark brown), and the overall particles reduced in size (larger particles broke down to create smaller particles) with an increase of 8% of fines (less than 0.5mm).

Where Do We Go From Here?

So, do wood substrate particles decompose? Yes. Do other organic substrate components like peat, bark, and coconut coir decompose? Also, yes. All organic (carbon-based) materials will decompose over time. We, as the users of organic substrates, are only borrowing these materials for a specified amount of time to serve a function — grow plants. The question is, how long does that take, and will it affect the growth of plants in containers, and if so, can management practices be altered to compensate for those changes?

Aging and degradation of wood begins with the cutting of the tree. Our aim is to slow that degradation rate long enough to effectively use these materials. With all the factors that can influence the decomposition of wood substrate materials, it should also be noted that the processing of the wood can have a direct effect on the chemical and physical properties as described in this article. It is more common that processing parameters (heating, drying, reducing wood chemicals by various means, etc.) delay or reduce overall decomposition rates during production compared to freshly processed wood.