Substrate Selection Can Lead to Improved Greenhouse Water Reuse

City water quality can vary greatly by region and often requires pre-treatment before use, particularly for facilities with hydroponic systems. Photos: Resource Innovation Institute

Whether you are growing greens or cultivating cannabis, picking the right substrate and pinpointing the nutrient mix for your crop is crucial to maximizing yield and minimizing crop loss. If growers want to achieve water circularity, in which all water used for cultivation is recycled and reused for irrigation, there are several important steps to take from design to construction.

Resource Innovation Institute is a non-profit organization committed to cultivating a better future for all of humanity. Our consortium of members brings perspectives from across the field—uniting architects and engineers, growers and operators, researchers and analysts. Together, we lead the measurement, verification, and celebration of the world’s most efficient agricultural ideas. In this article, RII’s Technical Director and members of the organization’s Technical Advisory Council working groups highlight several ways growers can optimize effectiveness of substrate and set facilities up for water circularity.

Policies implemented by government agencies in some regions of the U.S. require growers to minimize water waste and capture water for reuse. For example, the Illinois Department of Agriculture regulations for cannabis cultivation facilities require indoor growers to create resource management plans, adopt sustainable water use policies, use automated watering systems, manage runoff, and recapture water waste.

While regulations may not apply to your greenhouse in your location, policies are evolving to address water management practices as climate change continues to threaten water resources across the globe. To minimize runoff, maximize effectiveness of substrate by selecting options with little or no leach, or consider a hydroponic irrigation approach. If water circularity requirements do apply to your facility, it is even more crucial to rebalance nutrient solutions for fertigation processes so recaptured water is properly retreated and free of pathogens.

Evaluate Water Source

The first consideration for any greenhouse grower is where water is coming from, how much can be used, and when it is available. Some growers use municipal water as their primary water source as it is readily abundant, reliable, and high-quality. However, city water quality can vary greatly by region and often requires pre-treatment before use, particularly for facilities with hydroponic systems. Greenhouses in rural locations may use water from private wells, or receive deliveries of water. RII’s 2021 Cannabis Water Report co-authored with New Frontier Data and the Berkeley Cannabis Research Center, reported that 40% of PowerScore users growing cannabis use municipal potable water, more than 30% use well water, and 20% use natural sources of surface water like ponds.

According to RII Technical Advisory Council member Silver Bullet Water Treatment, “if using well water, greenhouse growers should analyze well water quality, performance, consistency, and seasonality to determine what treatment, storage, and processing infrastructure should be implemented. If your operation calls for 10,000 gallons per day (GPD), but the well only produces 5,000 GPD, evaluate secondary water sources, site selection, or growth method to ensure this is not a bottleneck.”

Understand Wastewater Discharge

Not all local ordinances are the same, and many governing agencies are beginning to require reclaim, reuse, and/or treatment before discharge. This includes waste streams from source water treatment processes such as reverse osmosis reject streams. For example, cannabis facilities in Illinois are required to measure runoff from watering events and report runoff volume in water usage plans; commit that on average, watering events shall have no more than 20% of runoff of water; and commit to capturing HVAC condensate, dehumidification water, excess runoff, and other wastewater and filtering for reuse. In Oklahoma City, irrigation runoff must be reused or land applied and cannot be discharged.

Some facilities may be located in areas without access to municipal sewer access and must incorporate septic systems or leach fields into water management system designs. These systems have strict water quality requirements requiring pretreatment of most cultivation water, especially hydroponic wastewater. For example, in Massachusetts, regulations restrict what can and cannot be discharged to septic systems, and most irrigation runoff and concentrate from reverse osmosis systems will require alternative disposal methods. If wastewater discharge on-site is not an option, then hauling waste off or thermally evaporating may be a grower’s last resort. Both of these strategies can add significant capital and operational expenses.

“We have multiple Massachusetts projects on septic that require wastewater treatment. One facility is choosing to evaporate, one is hauling waste off-site. One facility is recapturing wastewater and applying membrane filtration for reuse, then evaporating the final waste,” notes Kyle Lisabeth, VP of Horticulture at Silver Bullet Water Treatment.

Reuse Wastewater

Regulations on discharge and reuse of wastewater vary by region, all the way down to the type of property and local ordinances. Reflecting these dynamic challenges, only 15% of PowerScore users report using on-site recycled water for cultivation activities.

There are several sources of wastewater in cultivation facilities that can be recaptured and reused, to both minimize discharge and to maximize water efficiency of operations. One source of wastewater is irrigation runoff, while a second source is reclaimed condensate from HVAC systems. Lisabeth says that “a new sealed greenhouse facility in Baltimore, MD, with access to very good quality city water we are working with is choosing to blend condensate reclaim with city water and process without reverse osmosis (RO) filtration. This treatment system is highly efficient, economical, and results in little waste stream to manage.”

Some greenhouses are achieving comprehensive reclaim of all wastewater.

“In New Jersey, we are working with a client whose greenhouse has access to well water and a septic system. The property is zoned agriculture by local jurisdiction. We are working with local authorities to develop a water management plan that will allow select waste streams to be land applied and/or used as an input for secondary plant production on the property,” Lisabeth says.

Select Substrate

When growing in media, minimize leachate. Understand that both plant roots and select grow media will leach dissolved constituents that are challenging to remove and can negatively impact plant production in recirculation systems. This not only acts as a food source for unwanted microbial growth, but may negatively impact the nutrient balance and overall plant growth. Removing soluble organics, and/or choosing inert hydroponic inputs, will help mitigate potential issues.

Peat moss can be a challenging substrate for recirculating systems as it is organic and decays over time, can impact pH and degrade over plants’ life cycle, and leach soluble organics that impact nutrient recipe and provide a food source for unwanted microbial growth. Coco coir as a substrate can vary in quality and leach sodium, which can have negative implications for plants.

Understand the nutrient uptake of your plants. Lisabeth notes that over time, specific soluble nutrients will be taken up by plants faster than others

“If growers manage nutrient formulas by monitoring electrical conductivity (EC), we recommend frequent monitoring of macro and micronutrients using a qualified analytical laboratory,” he says.

Balance Hydroponic Systems

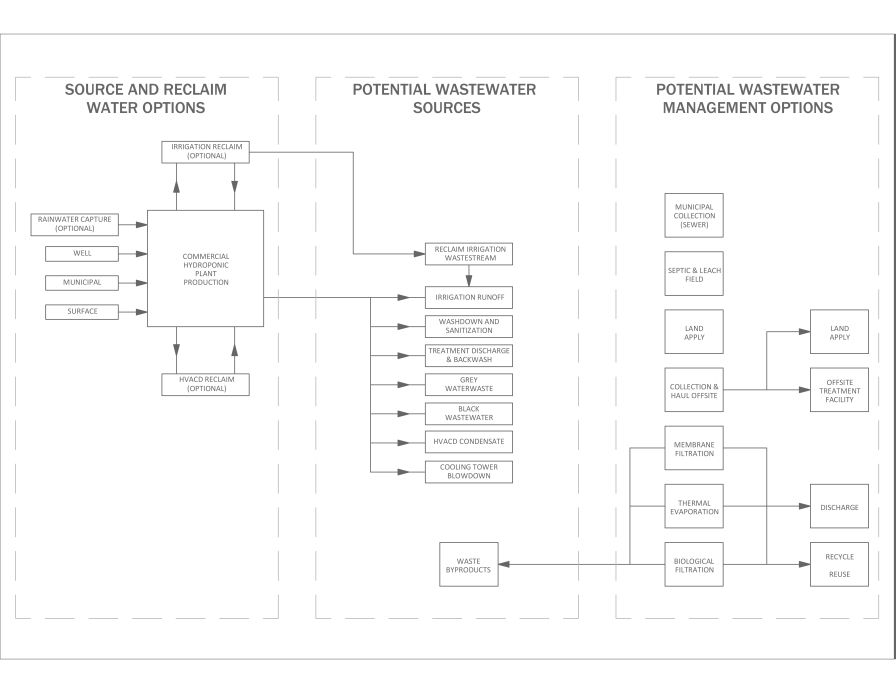

Both drain to waste and recirculating systems will ultimately result in a concentrated wastewater stream that cannot be used for hydroponic plant production. If left untreated, hydroponic waste streams can result in eutrophication and discharge may be limited. Local regulations, property location, building design, and cultivation strategy all determine which options are applicable. In the figure below, Silver Bullet Water Treatment shares some of the most common methods of managing waste streams in hydroponics:

Reclaim and Wastewater Management Options; Credit: Silver Bullet Water Treatment

Prepare for pathogens and manage algae, a non-pathogenic, yet unwanted microbial growth within hydroponic systems. Algae can alter the water pH and nutrient balance, hinder plant growth, cause maintenance issues, and provide food or harbor other unwanted microbial species. Prevent sunlight exposure as the first line of defense. Next, disinfect. Choose between several disinfection methods like ozone, oxidant chemistry, and UV sterilization which can be employed in recirculating hydroponic systems to control and prevent algae growth. It is crucial to ensure disinfection processes are compatible with nutrient formulas, compatible with cultivation processes, safe for operational staff, and reliable for long term operational use.

Learn More

In 2020, RII gathered global irrigation experts for the organization’s first Water Working Group to collaborate with New Frontier Data and the Berkeley Cannabis Research Center to produce Cannabis H2O: Water Use & Sustainability in Cultivation in early 2021. Greenhouse growers can learn tips for automating water systems in greenhouses in RII’s newest peer-reviewed Best Practices Guide on Automation & Controls for Cannabis Producers and watch the Best Practices on Optimizing Controls Systems and Verifying Savings workshop on-demand.

Funded by a USDA Conservation Innovation Grant, in August of 2022, RII will launch a Working Group focused on Water Reuse for Controlled Environment Agriculture. The members of the group will collaborate with RII to produce a new Best Practices Guide, which will be peer reviewed and published in early 2023.

Consider benchmarking your greenhouse operation’s water key performance indicators with PowerScore. Dig deeper by joining RII and participating in our Technical Advisory Council Working Groups.