Automation, Sustainability Driving Tag and Label Innovation in Plant Marketing

The last thing any greenhouse grower wants when they are trying to process and ship orders is hiccups in the process, which is why tag and labeling suppliers are committed to making things easier for their clients. Keep reading for a closer look at what some companies are doing to improve efficiency.

Great Lakes Label

Growers have wanted to get away from the labor-intensive hand application of the locking tag and of inserting pixie stakes, says Tony Cook, CEO and owner of Great Lakes Label. But they also know that consumer surveys acknowledge that 70% of the consumers want a tag to put in the ground or in a drawer for certain plants.

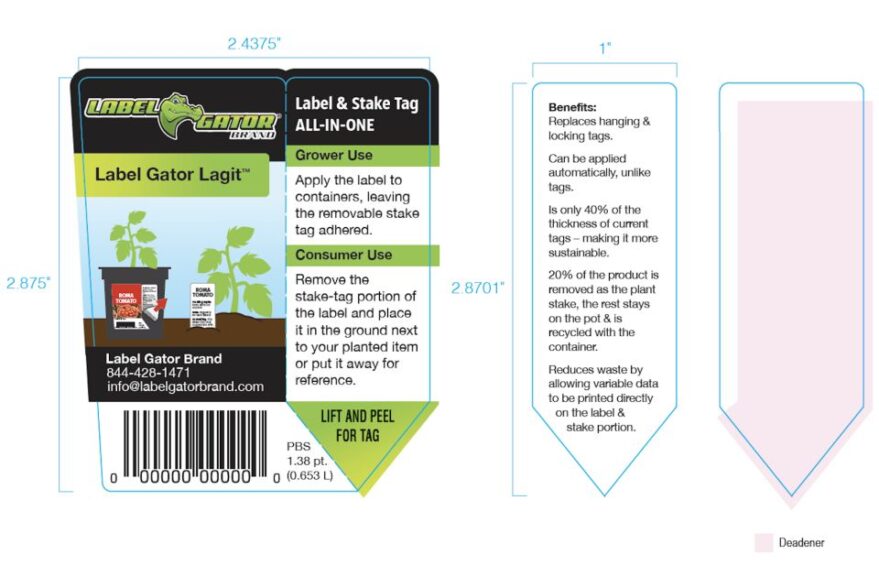

“The growers just want a product that they can automate and still fill the needs of the consumer,” Cook says. “This is why we created the Label Gator Lagit.”

The Label Gator Lagit (patent pending) consists of a label and a removable stake tag that can be used with the Label Gator’s automated systems. Consumers can peel off the stake tag and store it away for later use, or place it in the ground next to their plant. The Lagit can have variable data printed, which reduces the number of fully pre-printed tags or labels required. It can be automatically applied, which greatly reduces labor costs.

Great Lakes Label also recently introduced the Tag Labeler 3.0 to print and apply data on existing tags to help reduce growers’ inventory of tags and inventory obsolescence. The machine will print and apply up to 250 labels per minute. Print and apply technology reduces pre-printed label inventory by up to 90%. It is capable of installing all labels needed for variable data, including big-box retail program labels.

Advantage Label & Packaging

Advantage Label & Packaging has been at the forefront of the industry’s shift to full-color adhesive labels from the traditional plant stakes, according to Steve Kuperus at Advantage Label & Packaging.

“We introduced the Line Boss label applicator systems at Cultivate’22, which is being used by growers across the U.S. and Canada to apply the adhesive labels,” Kuperus says. “We have automated the process to apply full-color adhesive labels to pots and trays, which eliminates multiple people from performing the manual task of tagging.”

The labels make a more attractive presentation at retail, are more cost effective than traditional plant stakes, and provide a labor savings solution in a time when growers really need it, Kuperus says.

When auto-applying the adhesive labels to pots in trays, the Line Boss applies labels to the pots on both sides of the tray and can be connected in line with the soil filling equipment and planting line. Traditionally, growers had to manually add the plant stake and the addition of a secondary adhesive label for the grower information, barcode, retail, etc., on every pot.

“The growers we work with tell us they have eliminated two to four people from their planting lines,” Kuperus says. “It’s not that they no longer need those people, they just need them doing something else, and in this tight labor market that is a great way to free up employees. It also makes for a quick return on investment (ROI) on the equipment.”

WestRock

Labor, supply chain, and inventory management continue to be the biggest issues the team at WestRock faces.

“We work with each grower individually to understand their specific challenges and craft a solution leveraging the expertise of WestRock’s inventory management and digital solutions teams,” says Laura Wright, Marketing Manager – Home & Garden at WestRock. “We thoroughly test proposed solutions with growers before moving to full implementation.”

WestRock recently introduced Rockline Label Applicators, which are designed to help reduce labor costs, increase production speed, and grow sales. Three configurations are available with the ability to print pre-printed and inline printed labels to pots of various sizes and configurations. There are also options available to verify barcode readability.

When it comes to tags, WestRock’s goal is to reduce single-use plastic by 84%. The company has developed two materials that are patent-pending for horticulture applications. (Additional testing will be required on the final printed tag to demonstrate industrial compostable. Some composters may not accept tags for composting.):

- Fenix Fiber – Suitable material for nursery tags; durable, 79% plant-based solution with 84% plastics reduction

- Fenix Bio – Suitable for locking tags. Polylactic acid (PLA) base material is BPI-certified compostable and reduces fossil fuel plastic use by 84%.

MasterTag

“Many growers are experiencing staffing issues and looking closely at automation options at their location,” says Gerry Giorgio, Creative Director at MasterTag. “MasterTag can provide the proper adhesive labels for those customers who automate the application of these labels.”

Giorgio also notes that many retailers now require UPC codes, retail price points, and container volumes.

“Many of our customers have this applied to their tags, and this variable information can be changed by the customer at our online store,” he says.

The “no-touch” tag feature at MasterTag uses the company’s expanding managed inventory program.

“We inventory the full line of a customer’s tags and ship direct to their customer,” Giorgio says. “They get on-time delivery of the exact tags needed for the plants that they shipped.”

HIP Labels

According to Bob Lovejoy, President and owner of HIP Labels, growers are looking for non-plastic material options for custom packaging. He notes that governments across the world are taking various positions – some very aggressive (eliminating plastics), some longer-term timeframes, but almost all countries have their sights set on eliminating plastic packaging from consumer products.

“We have multiple projects in place, intending to provide several options to plastic for the next generation of horticultural tagging and labeling,” Lovejoy says.

HIP Labels’ newest tag – WoodTag – is the first non-plastic, recycled substrate in the horticulture market. It has a smaller carbon footprint to produce than plastic, and has a water-based, solvent-free coating for water resistance.

“We enjoyed fabulous interest and reviews from interested growers at Cultivate,” Lovejoy says. “Two very large growers introduced new product lines that included WoodTag this spring. They both enjoyed positive results in some measure driven by environmentally conscious consumers influenced by our WoodTag paper product. We expect this unique material to play an important role in our future.”